Why Do Your Reflective Tapes Always Fail?

Reflective tape plays a critical role in road safety, factory management, and vehicle visibility. However, many procurement officers and vehicle owners face a common issue: the tape looks bright when first applied, but within a few weeks, the edges start peeling, or the surface gets scratched, causing it to lose its reflectivity.

Not all reflective tapes are created equal. To find the best solutions for different environments, we conducted real-world application tests on three representative market brands (Type A, B, and C). This analysis reveals their characteristics and provides professional application techniques to solve common pain points like “peeling” and “bubbling.”

Contender A: The Anti-Scratch & Durable Type

Best For: Truck beds, high-traffic walkways, and corners prone to kicking or friction.

【Performance Analysis】

The core design of Type A is “Surface Protection.” Unlike standard reflective tapes with exposed reflective layers, Type A features a special anti-scratch plastic film coating. In friction simulation tests involving cargo handling, Type A showed the least amount of surface damage, maintaining its basic reflective performance over the long term.

【Identified Issue: End-Point Stress Peeling】

- Problem Description: Due to the protective film, the material has higher rigidity (elastic memory). If applied using standard flat methods, the stress concentrates at the “start” and “end” points of the tape. This causes the adhesive to fail at these points, leading to curling or peeling.

【Pro Solution: The Dual Reinforcement Method】

Our tests confirmed that standard application does not work well for Type A. You must use the following techniques to overcome the material’s rebound force:

Technique 1: Reverse Pressure (Breaking the Memory)

- Principle: Before peeling off the backing, curl the entire strip backwards (towards the non-adhesive side) and apply pressure. This breaks the material’s physical memory and reduces the rebound force after application.

Technique 2: The Film Sealing Method (Highly Recommended)

- Principle: Use the tape’s own surface plastic film to seal the cut edges at the start and end, which are most prone to peeling.

- Visual Guide:

Plaintext

[Step 1] When cutting, do not cut the transparent surface film flush with the reflective layer.

Leave about 0.5cm of extra transparent film.

[========Reflective Body========]-- (Extra Film) -->

[Step 2] After applying the body, fold the extra film down to wrap around and seal the cut edge.

[========Reflective Body========]

↓

(Fold film down to seal the edge)

↓

[___________Target Surface___________]

- Test Result: Samples applied using this “Sealing Method” showed zero detachment during the test period.

Contender B: The High-Intensity Warning Type

Best For: High road signs, flat walls, and warning zones out of human reach.

【Performance Analysis】

Type B excels in optical performance. Its reflective unit structure provides a remarkably high coefficient of retroreflection. Under night-time vehicle headlights, its visual brightness is significantly superior to the other two types. Additionally, its initial adhesion is very strong on flat surfaces.

【Identified Issue & Critical Taboo】

- Problem Description: To achieve maximum brightness, Type B lacks a hard protective layer, making the surface fragile and easily damaged by scratching.

- Critical Operation Taboo: We found that many users apply a layer of clear packing tape over Type B to “protect” it. This is a mistake.

- Reason: The extra layer of tape alters the path of light entry and refraction, causing a drastic drop in reflectivity (visible darkening). Type B must be applied “naked” to function correctly.

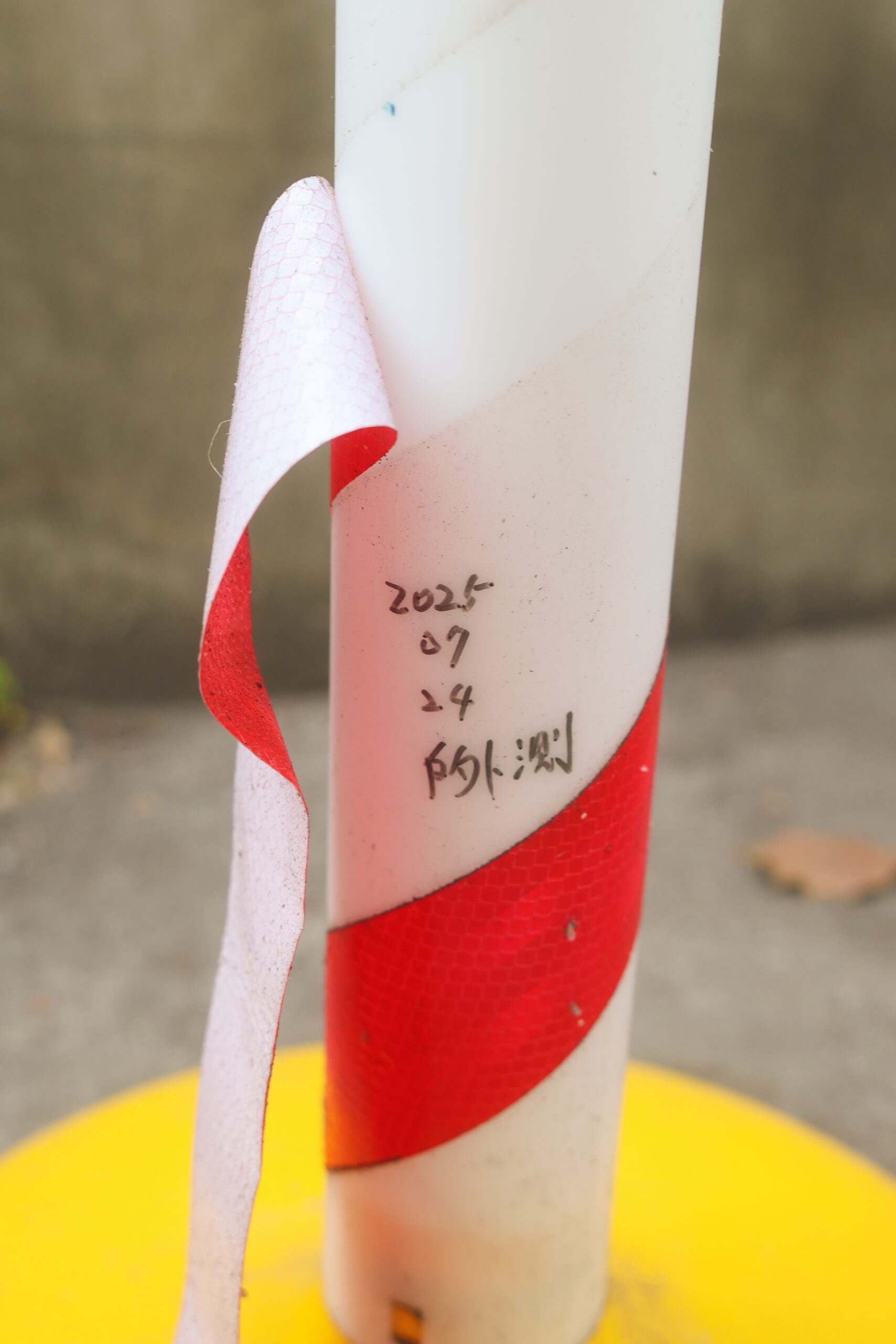

Contender C: The Conformable Cylindrical Type

Best For: Utility poles, bollards, and any curved surfaces.

【Performance Analysis】

For non-flat objects like parking lot columns and crash barriers, Type C demonstrates excellent adaptability. Its material is soft with high ductility, allowing it to wrap tightly around curves without creating opposing tension. This solves the issue of rigid tapes failing to stick to round pillars.

【Identified Issue: High Application Difficulty】

- Problem Description: Because the material is soft and the adhesive is strong, peeling off the backing all at once often traps air in the middle. This creates bubbles and bumps that are impossible to remove, affecting both aesthetics and reflective uniformity.

【Pro Solution: The “Screen Protector” Method】

- Recommended Steps:

- Align: Position the tape and peel off only the first 2 cm of the backing to fix the starting point.

- Advance: Use a squeegee (or your thumb) to apply steady pressure, pushing from the applied area toward the unapplied area.

- Sync: Use your other hand to slowly peel off the remaining backing in sync with the squeegee’s movement. “Peel, Press, Advance.” Do not rush.

Summary: Choosing the Best Material for the Scenario

To help you decide, we have summarized the test results in the table below:

| Criteria | Type A (Anti-Scratch) | Type B (High-Intensity) | Type C (Conformable) |

| Core Advantage | Wear-resistant, long lifespan | Highest reflectivity, extremely bright | Soft material, perfect for curves |

| Main Limitation | High stress at endpoints causes peeling | Surface is delicate; cannot use protective tape | Prone to bubbling if applied poorly |

| Best Scenario | High Friction Areas: Truck beds, walkway corners | High/Flat Areas: Hanging signs, wall warnings | Cylindrical Objects: Utility poles, bollards |

| Key Tip | Must seal the endpoints (See sealing method) | Keep surface clear; do not cover with tape | Use the “Peel & Press” slow method |

Final Recommendations for Buyers and Users

When selecting reflective tape, prioritize “Surface Shape” and “Brightness Requirements”:

- If the area is frequently kicked or scraped by cargo, you must choose Type A (Anti-Scratch). Take the extra time to seal the endpoints properly; this will save you the cost of repeated repairs later.

- If you are applying it to round pillars, do not hesitate—choose Type C (Conformable) so it won’t peel up.

- If you need strong long-distance warning visibility and the location is unlikely to be touched, Type B (High-Intensity) is your best choice.