2025 High-Visibility Materials White Paper: Principles, Formulations, and Applications of Daylight Fluorescent HDPE — From Safety Chains to Brand Displays

In the fast-evolving era of AI and smart cities in 2025, visibility and safety are no longer “standard requirements” but competitive advantages. High-visibility materials are reshaping the way construction sites, traffic management, event setups, and retail branding operate.

This article provides an in-depth look at the principles, weather-resistant formulations, application scenarios, and procurement considerations of daylight fluorescent HDPE chains.

What Is “Fluorescence”? Key Differences from Phosphorescence and Regular Pigments

Fluorescent pigments are substances that absorb energy from UV or short-wavelength visible light and instantly re-emit it as longer-wavelength visible light. This mechanism makes them appear “glowing” even under normal lighting.

Phosphorescent (glow-in-the-dark) pigments: Store energy and release it slowly in the dark, unlike fluorescence, which requires continuous light activation.

Regular pigments: Only reflect light, without glowing under UV.

Pearlescent or metallic pigments: Create shimmer through reflection but do not fluoresce.

Daylight Fluorescent Pigments: Why They Glow Even Under Normal Light

Unlike conventional fluorescent pigments that require UV activation, daylight fluorescent pigments exhibit extreme brightness and saturation under natural or artificial white light.

Color range: Neon yellow and green are the most stable; red, pink, and blue tend to be less lightfast.

Chemical composition: Coumarin, rhodamine, fluorone, and related dye molecules embedded in resin carriers.

Optical properties: Reflect and convert part of the visible spectrum, achieving 2–3x brightness compared to regular pigments.

Why HDPE × Fluorescent Pigments Are the Perfect Match

High-Density Polyethylene (HDPE) is widely used for safety and display products when combined with fluorescent pigments:

Application guideline: Choose low MI HDPE for long-term outdoor use; high MI for lightweight or short-term event setups.

Process compatibility: Fluorescent masterbatches (1–5%) can be added to HDPE for injection molding or extrusion.

Melt Index (MI) impact:

High MI (better flow): Easier dispersion, brighter colors, but slightly weaker weather resistance.

Low MI (higher molecular weight): Better outdoor durability, though dispersion is harder to control.

How to Prevent Fading: Weather-Resistant Formulations

UV exposure is the primary challenge for fluorescent pigments. Solutions include:

Process control: Maintain processing temperatures at 190–230°C to avoid thermal degradation of dyes.

High lightfast pigments: Encapsulated or microencapsulated fluorescent pigments.

UV absorbers (UVA): Convert UV into heat, reducing pigment degradation.

HALS (Hindered Amine Light Stabilizers): Neutralize free radicals, protecting both pigment and polymer.

🔍 Testing Methods

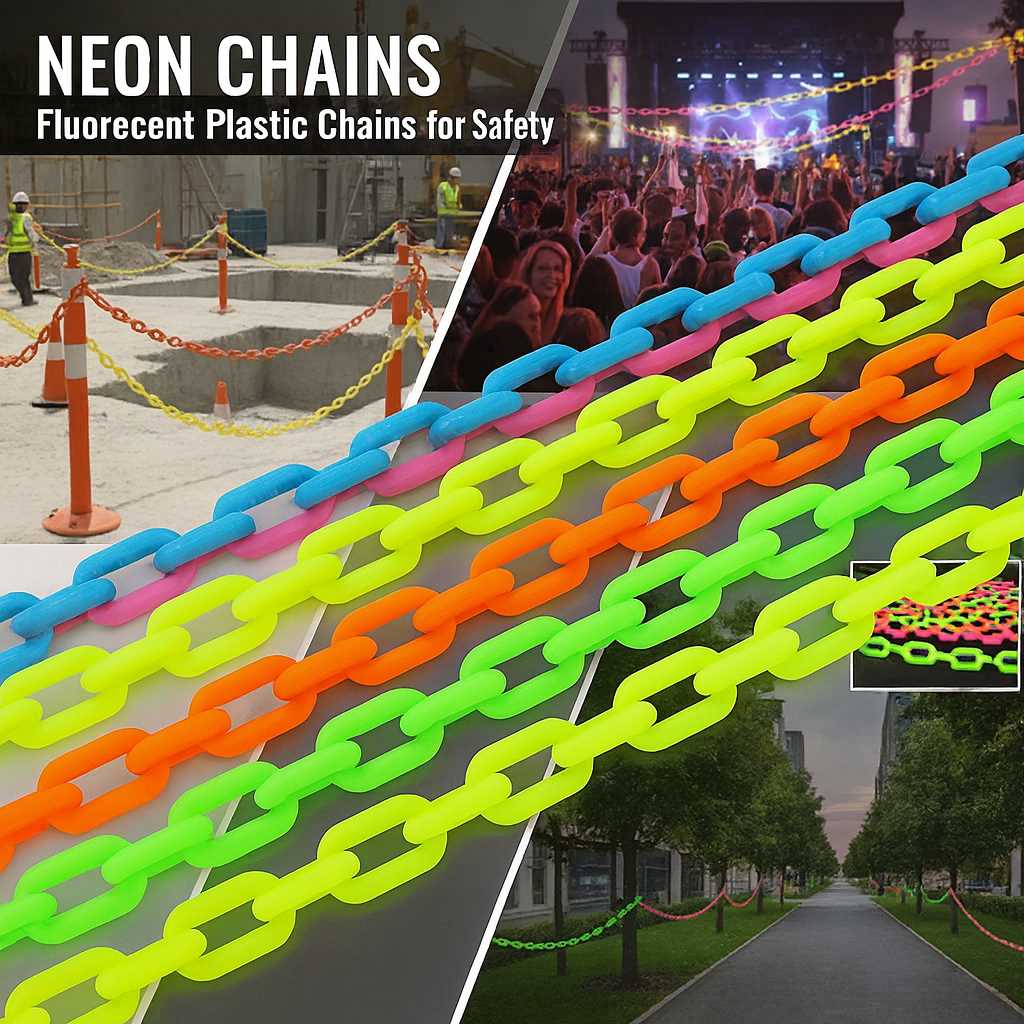

Six Key Application Scenarios: From Safety to Branding

HDPE fluorescent chains are more than just tools for safety; they’re versatile assets for enhancing brand visibility and managing events.

1. Safety & Construction Site Control

- Application: Construction sites, temporary roadblocks, traffic guidance.

- Color Strategy: Fluorescent yellow/orange provides high visibility and immediate recognition to ensure the safety of personnel and vehicles.

2. Event & Exhibition Management

- Application: Crowd control at music festivals, booth zoning, stage props.

- Color Strategy: Fluorescent pink/blue creates a strong visual impact that aligns perfectly with event or brand themes.

3. Retail & Brand Identification

- Application: High-recognition packaging, pop-up store decor, and product display zone demarcation.

- Color Strategy: Chain colors can align with your brand’s corporate identity (CI) to strengthen brand image.

4. Gardening & Agriculture

- Application: Marking plants or creating temporary fences on farmland.

5. Education & Toys

- Application: Color-learning tools for early childhood education and outdoor play props.

6. Art & DIY Projects

- Application: Installations, accessories, and other creative projects.

How to Choose the Right Specs for Your Project

Don’t just pick a chain at random. Choosing the right specifications ensures your investment pays off.

- 6mm Lightweight Chains: These are easy to carry and ideal for event planning, warehousing, and indoor safety zoning where a high tensile strength isn’t required.

- 8mm Heavy-Duty Chains: With superior tensile strength, these are the ideal choice for construction, traffic control, and heavy-duty outdoor perimeters.

Procurement Guide: Quality Is a B2B Buyer’s Top Priority

For procurement managers, choosing a product isn’t just about the item itself; it’s about risk management. Be sure to check for the following documents:

- Weathering Reports: Including QUV accelerated aging test and natural outdoor exposure data.

- Material Safety Certifications: Such as RoHS and REACH, to ensure the product is free of hazardous substances.

- Tensile Test Reports: To prove the product’s strength meets its stated specifications.

FAQs

Q1: Will the chain fade after 3 months of outdoor use?

A: Our formulations include UV absorbers (UVA) and HALS, validated by QUV and real-world outdoor tests. This extends the service life beyond 12 months, far surpassing the lifespan of standard products.

Q2: Why do red and blue colors fade faster than yellow?

A: The dye structures for red and blue are less UV-stable. Our best practice is to use yellow/green as base colors and accent with red/blue to balance aesthetics and durability.

Q3: Should I choose HDPE or PP material?

A: HDPE offers superior weather resistance for long-term outdoor use, while PP has advantages in rigidity and clarity. The choice depends on your specific application needs.

Conclusion: From Visibility to Safety and Value

HDPE fluorescent chains are no longer just safety barriers; they are strategic tools for brand visibility, event management, and market differentiation. By understanding the science of pigments, weather-resistant formulations, and application strategies, you can select the smartest solution for your projects.y, event management, and market differentiation.

By understanding pigment science, weather-resistant formulations, and application strategies, you can make smarter procurement and design choices in 2025’s competitive landscape.

📢 CTA — Call to Action

Looking for samples, weathering test reports, or custom color solutions?

Contact us today 👉sales@pinkbrand,com